INDUSTRIAL

Instrumentation

An analyzer is a tool used to analyze data. For example, a gas analyzer tool is used to analyze gases. It examines the given data and tries to find patterns and relationships. An analyser can be a piece of hardware or software. Autoanalysers perform their work with little human involvement. Analysis can be done directly on samples or the analyser can process data acquired from a remote sensor. The source of samples for automatic sampling is commonly some kind of industrial process.

An electrical cable is an assembly of one or more wires running side by side or bundled, which is used to carry electric current. A cable assembly is the composition of one or more electrical cables and their corresponding connectors.

A programmable logic controller (PLC) or programmable controller is an industrial computer that has been ruggedized and adapted for the control of manufacturing processes, such as assembly lines, machines, robotic devices, or any activity that requires high reliability, ease of programming, and process fault diagnosis. PLCs can range from small modular devices with tens of inputs and outputs (I/O), in a housing integral with the processor, to large rack-mounted modular devices with thousands of I/O, and which are often networked to other PLC and SCADA systems. They can be designed for many arrangements of digital and analog I/O, extended temperature ranges, immunity to electrical noise, and resistance to vibration and impact. Programs to control machine operation are typically stored in battery-backed-up or non-volatile memory.

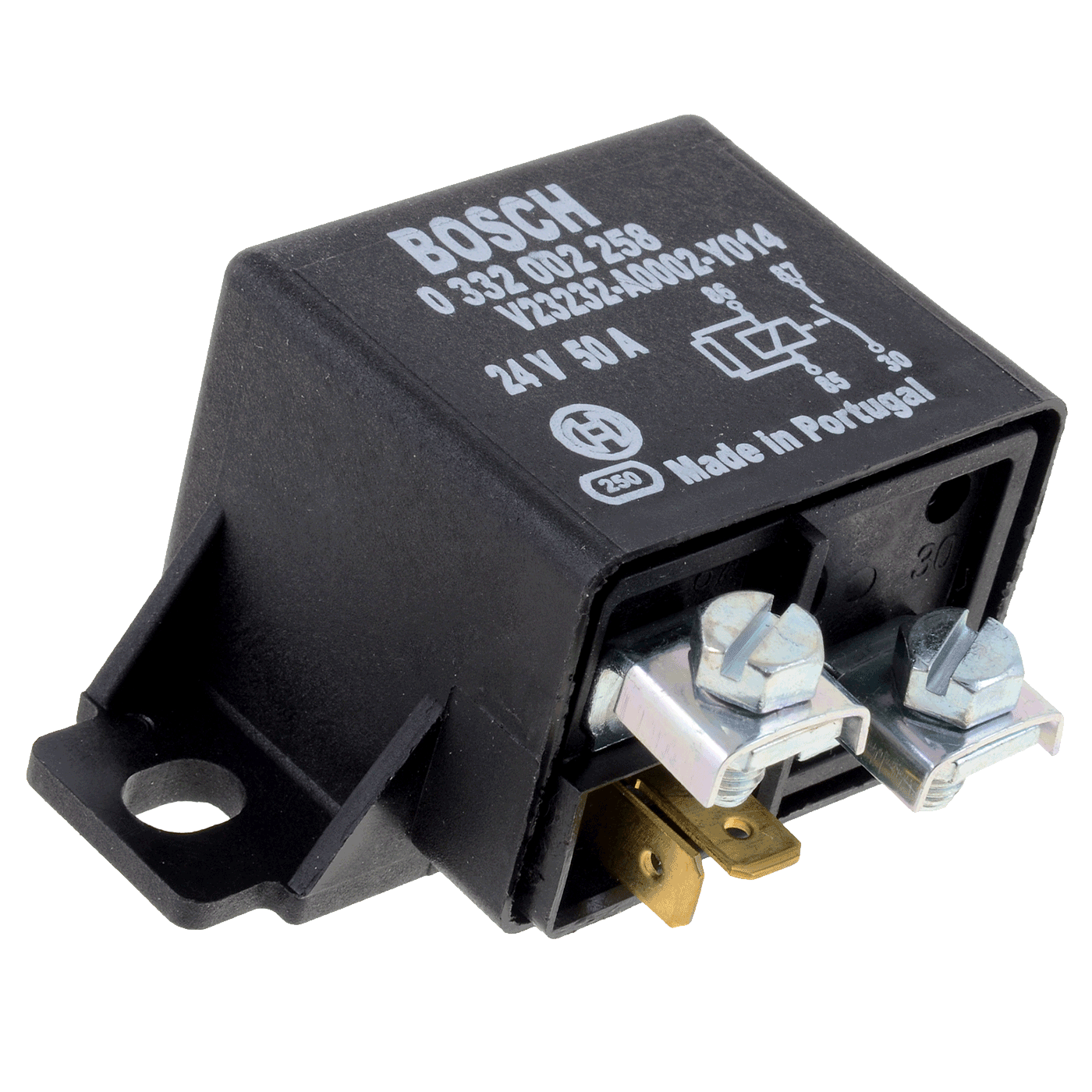

A relay is an electrically operated switch. It consists of a set of input terminals for a single or multiple control signals, and a set of operating contact terminals. The switch may have any number of contacts in multiple contact forms, such as make contacts, break contacts, or combinations thereof. Relays are used where it is necessary to control a circuit by an independent low-power signal, or where several circuits must be controlled by one signal. Relays were first used in long-distance telegraph circuits as signal repeaters: they refresh the signal coming in from one circuit by transmitting it on another circuit. Relays were used extensively in telephone exchanges and early computers to perform logical operations.

Electrical

An electric motor is an electrical machine that converts electrical energy into mechanical energy. Most electric motors operate through the interaction between the motor’s magnetic field and electric current in a wire winding to generate force in the form of torque applied on the motor’s shaft. Electric motors can be powered by direct current (DC) sources, such as from batteries, or rectifiers, or by alternating current (AC) sources, such as a power grid, inverters or electrical generators. An electric generator is mechanically identical to an electric motor, but operates with a reversed flow of power, converting mechanical energy into electrical energy. Electric motors may be classified by considerations such as power source type, internal construction, application and type of motion output. In addition to AC versus DC types, motors may be brushed or brushless, may be of various phase (see single-phase, two-phase, or three-phase), and may be either air-cooled or liquid-cooled.

A circuit breaker is an electrical safety device designed to protect an electrical circuit from damage caused by an overcurrent or short circuit. Its basic function is to interrupt current flow to protect equipment and to prevent the risk of fire. Unlike a fuse, which operates once and then must be replaced, a circuit breaker can be reset (either manually or automatically) to resume normal operation. Circuit breakers are made in varying sizes, from small devices that protect low-current circuits or individual household appliance, up to large switchgear designed to protect high voltage circuits feeding an entire city. The generic function of a circuit breaker, or fuse, as an automatic means of removing power from a faulty system is often abbreviated as OCPD (Over Current Protection Device). a switch is an electrical component that can disconnect or connect the conducting path in an electrical circuit, interrupting the electric current or diverting it from one conductor to another. The most common type of switch is an electromechanical device consisting of one or more sets of movable electrical contacts connected to external circuits. When a pair of contacts is touching current can pass between them, while when the contacts are separated no current can flow. Switches are made in many different configurations; they may have multiple sets of contacts controlled by the same knob or actuator, and the contacts may operate simultaneously, sequentially, or alternately. A switch may be operated manually, for example, a light switch or a keyboard button, or may function as a sensing element to sense the position of a machine part, liquid level, pressure, or temperature, such as a thermostat. Many specialized forms exist, such as the toggle switch, rotary switch, mercury switch, push-button switch, reversing switch, relay, and circuit breaker. A common use is control of lighting, where multiple switches may be wired into one circuit to allow convenient control of light fixtures. Switches in high-powered circuits must have special construction to prevent destructive arcing when they are opened.

A transformer is a passive component that transfers electrical energy from one electrical circuit to another circuit, or multiple circuits. A varying current in any one coil of the transformer produces a varying magnetic flux in the transformer’s core, which induces a varying electromotive force across any other coils wound around the same core. Electrical energy can be transferred between separate coils without a metallic (conductive) connection between the two circuits. Transformers are most commonly used for increasing low AC voltages at high current (a step-up transformer) or decreasing high AC voltages at low current (a step-down transformer) in electric power applications, and for coupling the stages of signal-processing circuits. Transformers can also be used for isolation, where the voltage in equals the voltage out, with separate coils not electrically bonded to one another. Transformers have become essential for the transmission, distribution, and utilization of alternating current electric power. A wide range of transformer designs is encountered in electronic and electric power applications. Transformers range in size from RF transformers less than a cubic centimeter in volume, to units weighing hundreds of tons used to interconnect the power grid.

Motor drive means a system that includes a motor. An adjustable speed motor drive means a system that includes a motor that has multiple operating speeds. A variable speed motor drive is a system that includes a motor and is continuously variable in speed. If the motor is generating electrical energy rather than using it – this could be called a generator drive but is often still referred to as a motor drive. Sometimes this is confused with a Variable Frequency Drive(VFD) or Variable Speed Drive(VSD) which describes the electronic portion of the system that controls the speed of the motor. More generally, the term drive, describes equipment used to control the speed of machinery. Many industrial processes such as assembly lines must operate at different speeds for different products. Where process conditions demand adjustment of flow from a pump or fan, varying the speed of the drive may save energy compared with other techniques for flow control. Where speeds may be selected from several different pre-set ranges, usually the drive is said to be adjustable speed. If the output speed can be changed without steps over a range, the drive is usually referred to as variable speed. Adjustable and variable speed drives may be purely mechanical (termed variators), electromechanical, hydraulic, or electronic. Sometimes motor drive refers to a drive used to control a motor and therefore gets interchanged with VFD or VSD.

Mechanical

Reliable Flow Control with Durable Brass Construction

The Brass Ball Valve – 2PCS Type is designed for efficient and long-lasting performance in various industrial and commercial applications. Made from high-quality HP59-1 brass, this valve provides excellent durability, corrosion resistance, and reliable flow control. With its solid brass ball and PTFE sealing, the valve ensures smooth operation, minimal leakage, and dependable performance under moderate pressure conditions. The 2PCS design also allows for easy maintenance and installation, making it an ideal choice for diverse fluid control systems. The Brass Ball Valve – 2PCS Type is a versatile valve suitable for a range of industries, providing reliable flow control for water, gas, and other non-corrosive fluids. With its sturdy brass build, precision flow control, and excellent sealing properties, the Brass Ball Valve – 2PCS Type is an outstanding choice for industries requiring durable and reliable valve solutions.

Key Features:

- Heavy-Duty Brass Construction: Made from HP59-1 brass, offering robust durability, resistance to corrosion, and long-lasting performance in demanding environments.

- Solid Brass Ball: The solid HP59-1 brass ball ensures consistent flow control and reliable sealing for both liquid and gas applications.

- Brass Shaft: The brass shaft enhances the valve’s structural integrity, offering strength and corrosion resistance for extended use.

- Reliable Sealing: PTFE sealing material provides superior leak prevention and chemical resistance, ensuring smooth operation over time.

- Pressure Rating: Designed to handle PN16 pressure, suitable for low- to medium-pressure systems.

- Manual Lever Operation: Equipped with a lever for easy manual control, allowing for precise on/off functionality and quick regulation of flow.

- Threaded End Connection: Features BSPT (British Standard Pipe Thread) threads for secure and leak-proof connections in various pipeline systems.

Applications & Industries:

- Plumbing Systems: Perfect for residential, commercial, and industrial plumbing applications, ensuring efficient water flow control in distribution and piping systems.

- Water Supply & Treatment: Commonly used in municipal water supply networks, irrigation systems, and wastewater treatment plants due to its durability and leak-proof performance.

- HVAC Systems: Ideal for controlling the flow of water, air, and gas in heating, ventilation, and air conditioning systems, providing efficient regulation in thermal systems.

- Compressed Air Systems: Reliable for use in compressed air systems, ensuring stable performance and pressure control.

- General Industrial Applications: Suitable for various industrial processes, including water management, fluid handling, and other moderate-pressure applications where brass valves are preferred.

- Gas Handling: Effective in controlling the flow of non-corrosive gases in industrial and commercial gas systems.

Reliable Backflow Prevention for Secure Fluid Flow Control

The Brass Lift Check Valve is designed for efficient and dependable backflow prevention in fluid systems. Built from high-quality HP59-1 brass, this valve offers excellent durability, corrosion resistance, and longevity. Its lift check mechanism allows fluid to flow in one direction, automatically closing to prevent reverse flow, protecting systems from damage and ensuring seamless operation. This valve is an ideal choice for a wide range of industrial and commercial applications where backflow prevention is critical.

Key Features:

- Heavy-Duty Brass Body: Made from HP59-1 brass, providing superior resistance to corrosion, wear, and mechanical stress, ensuring a long service life.

- Brass Disc & Shaft: Both the disc and shaft are constructed from HP59-1 brass, ensuring smooth operation and reliable sealing over time.

- Brass Sealing: The brass sealing ensures a tight, leak-proof closure, maintaining system integrity under varying pressure conditions.

- Pressure Rating: Rated for PN16, making it suitable for medium-pressure applications in diverse industries.

- Threaded End Connection: BSPT (British Standard Pipe Thread) threads ensure a secure, leak-free connection, compatible with various pipeline systems.

Applications & Industries:

- Water Supply & Treatment: Ideal for use in water distribution systems, preventing backflow and maintaining water purity in residential, commercial, and industrial settings.

- Irrigation Systems: Ensures proper water flow in irrigation systems, protecting equipment and maintaining efficient operation by preventing reverse flow.

- Plumbing Systems: Perfect for residential and commercial plumbing, ensuring one-way flow in piping systems to prevent water hammer and protect pumps and equipment.

- HVAC Systems: Helps control fluid flow in heating, ventilation, and air conditioning systems, providing efficient backflow prevention to safeguard equipment and improve system efficiency.

- Industrial Processing: Used in industrial processes to regulate the flow of fluids like water and non-corrosive liquids, preventing reverse flow and maintaining process integrity.

Dependable Backflow Prevention with Durable Brass Construction

The Brass Swing Check Valve is engineered to provide reliable backflow prevention in a wide range of fluid handling systems. Made from high-quality HP59-1 brass, this valve offers superior corrosion resistance, strength, and durability, ensuring long-lasting performance in industrial and commercial applications. Designed to allow fluid to flow in one direction and automatically prevent reverse flow, this swing check valve is essential for protecting pipelines and maintaining system integrity.

Key Features:

- Heavy-Duty Brass Body: Constructed from HP59-1 brass, known for its excellent strength, corrosion resistance, and durability in harsh conditions.

- Brass Disc & Shaft: Both the disc and shaft are made from HP59-1 brass, providing reliable, wear-resistant operation and ensuring the valve opens and closes smoothly.

- Brass Sealing: The valve’s sealing components are made from HP59-1 brass, ensuring leak-proof operation and minimal maintenance.

- Pressure Rating: Rated for PN16 pressure, suitable for medium-pressure applications across various industries.

- Threaded Connection: BSPT (British Standard Pipe Thread) threads ensure secure, leak-free connections in pipeline systems.

Applications & Industries:

- Water Supply & Distribution: Prevents backflow in residential, commercial, and industrial water supply systems, maintaining the purity of water and preventing contamination.

- Irrigation Systems: Used in agricultural and landscape irrigation systems to control water flow and prevent reverse flow, ensuring efficient water use.

- HVAC Systems: Ideal for preventing reverse flow in heating, ventilation, and air conditioning systems, ensuring efficient operation and protecting equipment.

- Plumbing Systems: Ensures proper flow direction in plumbing systems, preventing water hammer and protecting pumps, piping, and equipment from backflow damage.

Industrial Processing: Effective for fluid control in industrial systems handling water, oil, or non-corrosive liquids, maintaining the integrity of fluid transfer operations.

Reliable, Durable, and Efficient Flow Control

The Lug Butterfly Valve (LTD71X-10/16Q) is designed for optimal performance in a wide range of industrial applications. Engineered to handle high-pressure environments with ease, this valve is your go-to solution for efficient and reliable flow control.

Key Features:

- Heavy-Duty Construction: Made from robust ductile iron, ensuring durability and resistance to wear.

- Nickel-Plated Disc: Ductile iron disc with a secure pin connection, providing excellent corrosion resistance and extended lifespan.

- High-Performance Shaft: Constructed with SS420 stainless steel for strength and reliability.

- Versatile Pressure Handling: Rated for PN10, PN16, and 150LB, making it suitable for various pressure Premium Seat Material: 50% EPDM content, ensuring a tight seal and zero leakage.

- Easy Operation: Comes with a handle for straightforward manual operation.

- Protective Coating: Coated with Akzo Nobel brand epoxy resin spray for enhanced protection against environmental factors.

- 24-Month Warranty: Backed by a 24-month warranty, giving you peace of mind.

- 100% Pressure Tested: Every valve undergoes a rigorous pressure test to guarantee zero leakage.

Application & Industries:

The Lug Butterfly Valve (LTD71X-10/16Q) is designed for a variety of applications, making it ideal for controlling the flow of liquids and gases. This versatile valve can be used in both isolation and throttling applications, providing exceptional performance and reliability across a wide range of industries.

Water Treatment & Distribution: Ideal for regulating water flow in municipal, industrial, and commercial water systems.

HVAC Systems: Ensures precise control and efficient flow management in heating, ventilation, and air conditioning systems.

Chemical Processing: Suitable for handling non-corrosive chemicals and ensuring safe and efficient operations.

Oil & Gas: Performs well in downstream operations, managing flow in pipelines and processing facilities.

Food & Beverage Industry: Compatible with non-toxic media, making it perfect for applications in food and beverage production.

Marine & Shipbuilding: Durable design makes it suitable for use in harsh marine environments and ballast systems.

Durable, Reliable, and Built for Demanding Applications

The Metal Seat Gate Valve (Z41T-10Q) is engineered to provide robust and precise flow control in the most challenging industrial environments. With a rising stem design, this valve ensures smooth and reliable operation, making it an excellent choice for applications where visual indication of valve position is essential. Its rugged construction and metal seat design offer superior durability and performance, making it ideal for both fluid and gas applications.

Key Features:

- Rising Stem Design: The rising stem provides a clear visual indication of whether the valve is open or closed, making it perfect for above-ground installations and easy inspection.

- Heavy-Duty Body: Made from high-strength ductile iron, ensuring long-lasting durability and resistance to mechanical stress and impacts.

- Solid Wedge Construction: Features a robust ductile iron wedge, providing tight shutoff and reliable flow control.

- Brass Metal Seat: The brass seat delivers excellent sealing performance, reduced wear, and a longer lifespan, even in high-temperature and high-pressure applications.

- Durable Shaft Material: 2Cr13 stainless steel shaft ensures high strength and corrosion resistance, providing stability in demanding environments.

- Pressure Rating: Designed to withstand PN10 pressure, making it suitable for low- to medium-pressure systems.

- High-Quality Sealing: Equipped with EPDM sealing material, ensuring zero leakage and reliable operation in a wide range of media.

- Manual Operation: Operated using a handwheel for precise and easy manual control.

- Standard Face-to-Face Length: Complies with DIN F4 standards, making it easy to install and integrate into existing pipeline systems.

- Protective Coating: Coated with Akzo Nobel brand epoxy resin spray, offering excellent protection against corrosion and environmental factors.

- 24-Month Warranty: Comes with a 24-month warranty, assuring quality and reliability.

- 100% Pressure Tested: Each valve is pressure tested to ensure zero leakage and peak performance in all applications.

Applications and Industries:

The Metal Seat Gate Valve (Z41T-10Q) is built for versatility and can be used across a wide range of industries. Its reliable metal seat construction and robust design make it suitable for the following applications:

- Water Supply & Treatment: Ideal for regulating water flow in municipal water supply systems, treatment facilities, and irrigation networks.

- Industrial Fluid Handling: Excellent for handling a variety of industrial fluids, including non-corrosive chemicals and high-temperature media.

- Oil & Gas Industry: Performs well in upstream and downstream operations where tight sealing and zero leakage are critical.

- HVAC Systems: Suitable for controlling the flow of hot and cold water, steam, and other media in heating, ventilation, and air conditioning systems.

- Mining & Mineral Processing: Durable design makes it perfect for handling abrasive and high-pressure applications common in mining operations.

- Power Generation: Withstands high temperatures and pressures, making it ideal for power plants and other energy-related industries.

With its superior metal seat design, rising stem configuration, and durable construction, the Metal Seat Gate Valve (Z41T-10Q) is a reliable and long-lasting solution for critical flow control in demanding industrial environments. Choose this valve for exceptional performance and durability across a variety of applications.

Efficient Flow Control with Superior Sealing Performance

The Resilient Gate Valve (Z45X-10Q) is designed to provide exceptional sealing and reliable operation in a range of industrial applications. This non-rising stem valve features a robust construction and a unique wedge design, making it the ideal choice for ensuring tight shutoff and smooth flow control in water distribution and other critical systems. With its robust design, superior sealing capabilities, and easy operation, the Resilient Gate Valve (Z45X-10Q) is a trusted solution for managing the flow of liquids in various industries.

Key Features:

- Non-Rising Stem Design: Saves space and is suitable for underground or confined installations, providing reliable operation without affecting the stem height.

- Heavy-Duty Construction: Crafted from high-strength ductile iron for enhanced durability and resistance to mechanical wear and tear.

- Resilient Wedge: Ductile iron wedge lined with high-quality EPDM, ensuring tight sealing, zero leakage, and extended service life.

- Durable Shaft Material: Shaft made from 2Cr13 stainless steel, offering excellent corrosion resistance and structural integrity.

- Rated Pressure: Designed for PN10 pressure applications, making it suitable for low- to medium-pressure systems.

- Premium Sealing: EPDM sealing material ensures a leak-proof operation and provides resistance to water, chemicals, and other media.

- Manual Operation: Operated by a handwheel, allowing for easy and precise flow control.

- Standard Face-to-Face Length: Manufactured to DIN F4 standard for easy integration into existing pipeline systems.

- Protective Coating: Akzo Nobel brand epoxy resin spray offers superior corrosion protection, safeguarding the valve in harsh environments.

- 24-Month Warranty: Covered by a 24-month warranty, ensuring dependable performance and peace of mind.

- 100% Pressure Tested: Each valve undergoes stringent pressure testing to guarantee zero leakage and optimal performance.

Applications & Industries:

The Resilient Gate Valve (Z45X-10Q) is built for reliability and durability, making it perfect for a variety of industrial and municipal applications, including:

- Water Supply & Distribution: Ideal for controlling water flow in municipal water systems, water treatment facilities, and distribution networks.

- Wastewater Management: Suitable for wastewater systems where reliable shutoff and minimal leakage are essential.

- Fire Protection Systems: Performs well in fire water lines and other safety systems where dependable operation is crucial.

- Irrigation Systems: Provides efficient flow control in agricultural and landscape irrigation applications.

Industrial Fluid Handling: Suitable for a wide range of industrial processes where precise flow control and tight sealing are required.

Prevent Backflow with Reliable Flow Control

The Swing Check Valve (H44T-16Q) is engineered to provide effective backflow prevention and reliable performance in a variety of industrial applications. With a durable ductile iron body and brass sealing components, this valve ensures smooth operation and long service life, even in demanding environments. Designed to allow flow in one direction and automatically close to prevent reverse flow, the H44T-16Q is your trusted solution for safeguarding pipelines and systems. The Swing Check Valve (H44T-16Q) is an essential component for any system that requires dependable backflow prevention.

Key Features:

- Rugged Body Construction: The body is made from high-strength ductile iron, offering exceptional durability and resistance to mechanical stress and corrosion.

- Solid Disc Design: The ductile iron disc provides smooth flow and effective sealing, ensuring minimal pressure loss and reliable backflow prevention.

- Brass Sealing Material: The brass sealing offers excellent resistance to wear and corrosion, ensuring tight closure and zero leakage over extended use.

- Pressure Rating: Rated for PN16 pressure, making it suitable for medium-pressure applications.

- Protective Coating: Coated with Akzo Nobel brand epoxy resin spray, providing superior protection against environmental and chemical exposure.

- 24-Month Warranty: Backed by a 24-month warranty, ensuring reliable and long-lasting performance.

- 100% Pressure Tested: Each valve undergoes rigorous pressure testing to guarantee zero leakage and flawless operation in any application.

Applications & Industries:

The Swing Check Valve (H44T-16Q) is designed to provide reliable backflow prevention in a range of industries, making it suitable for protecting pipelines and systems from reverse flow. It is ideal for the following applications:

- Water Supply & Distribution: Prevents backflow in water pipelines, ensuring clean water supply and system protection in municipal and industrial water distribution networks.

- Wastewater Treatment: Effectively handles wastewater and non-corrosive liquids, providing reliable performance in wastewater treatment plants and sewage systems.

- Chemical & Petrochemical Industry: Suitable for handling various non-corrosive chemicals, ensuring safe flow control in chemical processing and handling applications.

- Oil & Gas Industry: Performs well in preventing backflow in pipelines and systems, maintaining system integrity in upstream and downstream operations.

- HVAC Systems: Ensures proper flow direction and prevents reverse flow in heating, ventilation, and air conditioning systems.

- Fire Protection Systems: Protects fire water lines and hydrant systems from backflow, ensuring readiness and compliance in fire safety systems.

Precision Flow Control with Durability You Can Trust

The Thread Ball Valve – 2PCS Type is built for robust and reliable performance in various industrial applications. Featuring a heavy-duty SS304 stainless steel construction, this valve is designed for longevity, corrosion resistance, and efficient flow control. The solid SS304 ball, combined with PTFE sealing, ensures smooth operation, minimal leakage, and optimal performance under high-pressure conditions. Whether you’re managing liquid, gas, or airflow, this ball valve offers exceptional durability and precision. The Thread Ball Valve – 2PCS Type is versatile and can be used across various industries where durable and precise flow control is essential.

Key Features:

- Heavy-Duty Body: Constructed from premium SS304 stainless steel, providing excellent resistance to corrosion and mechanical stress in demanding environments.

- Solid Ball Design: SS304 solid ball ensures smooth flow control and long-lasting durability, even in high-pressure systems.

- Corrosion-Resistant Shaft: SS304 shaft provides superior strength and protection against corrosion, ensuring reliable operation in harsh conditions.

- Reliable Sealing: Equipped with PTFE (polytetrafluoroethylene) sealing material for tight, leak-free performance and excellent chemical resistance.

- High-Pressure Rating: Rated for 1000WOG (Water, Oil, Gas), this valve is capable of handling high-pressure applications with ease.

- Lever Operation: Manual lever operation for easy and precise flow control, offering quick shut-off and regulation.

- Threaded Connection: BSPT (British Standard Pipe Thread) end connection ensures a secure and reliable fit, making it compatible with various industrial pipeline systems.

Applications & Industries:

- Water & Wastewater Management: Ideal for controlling water flow in treatment plants, distribution systems, and irrigation networks.

- Oil & Gas Industry: Suitable for handling oil, gas, and other hydrocarbons, offering reliable performance under high pressure in upstream, midstream, and downstream operations.

- Chemical Processing: With its PTFE sealing, this valve provides resistance to a wide range of chemicals, making it a perfect fit for chemical processing and handling.

- HVAC Systems: Used to control the flow of hot and cold water, air, and gas in heating, ventilation, and air conditioning systems.

- Food & Beverage Processing: Stainless steel construction ensures the safe handling of food-grade materials and liquids, making it ideal for use in sanitary environments.

- Industrial Manufacturing: Commonly used in factories and processing plants to regulate the flow of various liquids, gases, and compressed air in manufacturing operations.

Advantages:

Heavy body: Ductile iron

Nickel-plated disc

Ductile iron with a pin

Shaft: SS420

Pressure: PN10/PN16/150LB

Seat: 50% EPDM content

Operation: Handle

Akzo Nobel brand epoxy resin spray

24-month warranty

100% pressure test: Zero leakage

Additional information:

PN Rating (Pressure Nominal)

- PN 10 and PN 16 indicate pressure ratings in bar (1 bar = 14.5 psi).

- PN 10: Rated for a maximum pressure of 10 bar (145 psi).

- PN 16: Rated for a maximum pressure of 16 bar (232 psi).

- The PN rating is primarily used in European and metric-standard systems to denote the pressure class of components.

150LB: Class 150 is part of the American standard ANSI/ASME B16.5, indicating that the valve can handle a maximum pressure of approximately 150 psi at 20°C

The pressure capacity varies with temperature; as temperature increases, the pressure rating usually decreases.

Comparison and Application

PN 10 and PN 16 valves are often used in water distribution and low-pressure systems.

150-lb valves are used in medium to low-pressure applications, typically in industries following the ANSI/ASME standards.

Wafer Butterfly Valve (D71X-10/16Q)

Precision Flow Control for Industrial Applications

The Wafer Butterfly Valve (D71X-10/16Q) is expertly designed to deliver exceptional performance in a range of industrial environments. With a compact design and robust construction, this valve is an ideal choice for efficient flow control in both low- and high-pressure systems. Whether you need to regulate, isolate, or throttle flow, this versatile valve provides reliable operation and long-lasting durability. This wafer-style butterfly valve is versatile, lightweight, and easy to install, making it a preferred choice for numerous industries that require precise and reliable flow control.

Key Features:

- Heavy-Duty Body: Constructed from high-strength ductile iron, offering superior durability and resistance to mechanical stress.

- Nickel-Plated Disc: The ductile iron disc is nickel-plated for enhanced corrosion resistance and a longer service life, ensuring smooth operation and reliability.

- Reinforced Shaft: SS420 stainless steel shaft provides additional strength and stability under high-pressure conditions.

- Versatile Pressure Ratings: Designed to handle PN10, PN16, and 150LB pressure ratings, making it adaptable to a variety of applications.

- High-Quality Seat: Features a seat made with 50% EPDM content, delivering a tight seal and zero leakage performance.

- Easy Manual Operation: Equipped with a handle for precise manual operation, allowing for quick and effortless flow control.

- Protective Coating: The valve is coated with Akzo Nobel brand epoxy resin spray, providing excellent protection against corrosion and extending the valve’s lifespan.

- 24-Month Warranty: Covered by a 24-month warranty, ensuring confidence and peace of mind.

- 100% Pressure Tested: Each valve is rigorously pressure tested to guarantee zero leakage and flawless performance.

Application & Industries:

The Wafer Butterfly Valve (D71X-10/16Q) is suitable for a wide range of applications where reliable flow control is critical. Its design and features make it an excellent choice for use in:

- Water Treatment & Distribution: Ideal for managing and regulating the flow of water in water treatment plants, municipal water systems, and wastewater management.

- Chemical & Petrochemical Industries: Resistant to various chemicals and harsh media, making it suitable for chemical processing and petrochemical applications.

- HVAC Systems: Used in heating, ventilation, and air conditioning systems to regulate airflow and maintain efficient operation.

- Food & Beverage Production: Safe for use in handling non-toxic media and processing food-grade applications.

- Pulp & Paper Industry: Efficiently controls the flow of pulp, water, and chemicals used in the paper-making process.

- Marine & Shipbuilding: Withstands tough marine environments and is ideal for use in ballast water systems and shipboard fluid control.

Compact and Reliable Backflow Prevention for Industrial Applications

The Wafer Check Valve – Dual Plate is designed to provide effective backflow prevention with a compact design, making it ideal for use in space-constrained piping systems. Featuring a heavy-duty ductile iron body and a dual plate mechanism, this valve ensures smooth, reliable flow control while preventing reverse flow. With robust construction and EPDM sealing, the valve is capable of handling medium-pressure systems, offering durability and leak-proof performance across various applications.

Key Features:

- Dual Plate Design: The dual plate mechanism allows for efficient flow with minimal pressure loss while automatically closing to prevent backflow.

- Heavy-Duty Body: Constructed from ductile iron, offering enhanced strength, toughness, and durability for long-lasting operation, even in harsh conditions.

- Corrosion-Resistant Shaft: Made from SS416 stainless steel, the shaft provides excellent corrosion resistance and strength, ensuring reliable performance over time.

- EPDM Sealing: The valve features EPDM (ethylene propylene diene monomer) sealing material, ensuring a tight, leak-free closure and resistance to chemicals, heat, and weathering.

- Pressure Rating: Rated for PN16 pressure, making it suitable for medium-pressure applications in various industries.

Applications & Industries:

- Water Supply & Distribution: Ideal for municipal water supply networks and industrial water systems, preventing backflow and maintaining water quality and system integrity.

- Wastewater Management: Used in wastewater treatment plants to ensure proper flow direction and prevent contamination or damage caused by reverse flow.

- HVAC Systems: Perfect for heating, ventilation, and air conditioning systems, ensuring efficient flow of air, water, and other fluids while preventing reverse flow.

- Fire Protection Systems: Commonly used in fire protection piping systems to maintain water pressure and ensure that water flows in the correct direction when needed.

- Oil & Gas Industry: Suitable for controlling the flow of non-corrosive liquids and gases, ensuring efficient backflow prevention in pipeline systems.

- Chemical Processing: With its EPDM sealing, the valve is resistant to chemicals, making it ideal for handling various fluids in chemical and industrial processing systems.

Efficient Flow Control for Challenging Media

The Wafer Knife Gate Valve (PZ73X-10/16C) is designed to deliver reliable and effective flow control in applications involving viscous, abrasive, and slurry-like media. Its robust construction and sharp-edged knife design make it ideal for cutting through tough solids and ensuring smooth operation in demanding industrial environments. The valve’s compact wafer design also offers easy installation and reduced weight, making it a versatile solution for various industries. With its robust design, reliable sealing, and ability to handle challenging media, the Wafer Knife Gate Valve (PZ73X-10/16C) is an excellent choice for industries that require precise flow control and zero blockage in their processes.

Key Features:

- Rugged Body Construction: The body is made of WCB (Weldable Cast Steel), providing excellent strength and durability to withstand high-pressure and high-wear applications.

- Sharp Knife Design: The knife, also made from WCB, is engineered to cut through solid-laden media, preventing blockages and ensuring efficient flow control.

- Reinforced Shaft Material: 2Cr13 stainless steel shaft offers superior corrosion resistance and strength, ensuring long-lasting performance and stability.

- Reliable Sealing: EPDM sealing material provides a tight, leak-proof seal, making it suitable for applications involving water, non-corrosive chemicals, and slurry.

- Pressure Rating: Rated for PN10 pressure, the valve performs reliably in low- to medium-pressure systems.

- Manual Operation: Comes equipped with a handwheel, allowing for easy and precise manual operation and flow regulation.

- Protective Coating: Coated with Akzo Nobel brand epoxy resin spray for enhanced resistance to corrosion and environmental factors.

- 24-Month Warranty: Backed by a 24-month warranty, ensuring reliability and quality you can count on.

Applications & Industries:

The Wafer Knife Gate Valve (PZ73X-10/16C) is built for heavy-duty performance and is particularly suitable for applications where media contain solids, slurries, or viscous materials. Typical industries and applications include:

Mining & Mineral Processing: Ideal for handling slurry and abrasive materials, this valve performs exceptionally well in the mining industry for controlling flow in ore and tailings processing.

Pulp & Paper Industry: Effective for regulating the flow of pulpy media and wastewater, ensuring blockage-free operation in paper and pulp production.

Water & Wastewater Treatment: Suitable for managing water flow, sludge, and other solids-laden fluids in municipal and industrial wastewater treatment plants.

Chemical Processing: Capable of handling various chemicals and abrasive media, providing reliable flow control in chemical processing and handling applications.

Power Generation: Efficiently manages the flow of coal slurry, fly ash, and other abrasive media in power generation plants.

Food & Beverage Processing: This can be used to handle non-toxic, solid-containing media, making it ideal for applications in the food and beverage industry.